3D printing grew from the desire to accelerate industrial product development through rapid prototyping. It is often associated with the DIY culture of amateurs and hobbyists.

The main 3D printer technologies are Fused Deposition Modeling (FDM), Material Jetting, and Powder Bed Fusion. These technologies use lasers, plasma arcs, or electron beams to melt materials. Contact By3Design now!

Before the advent of rapid prototyping, design teams created makeshift prototypes by hand to show clients and collaborators their concepts. However, bringing these prototypes to life required the same processes, costs, and tooling as final-product manufacturing, making it prohibitive for many projects.

Rapid prototyping technologies like 3D printing are changing that, allowing product designers and engineers to transform their designs into prototypes quickly, at a fraction of the cost and without all the time-consuming setup involved in traditional methods. This allows them to test, refine and improve their designs to avoid costly design flaws.

Depending on the type of printing technology used, there are a number of different materials available to create a functional prototype for testing. These include standard plastics, such as ABS and PETG, used in stereolithography (SLA) and digital light processing (3D printing); metals, including aluminum and titanium, often produced with Selective Laser Melting or Direct Metal Laser Sintering; ceramics; waxes for investment casting; and composites, which combine the properties of different materials, such as carbon fiber reinforced plastics or ceramics.

Laminated Object Manufacturing, or LOM, is a distinct rapid prototyping method that layers adhesive-coated paper, plastic, or metal laminates together, layer by layer, to form a model or pattern. LOM is often used in industries such as automotive and aerospace for creating scale models, functional parts for testing, and prototypes of components that require a high level of detail.

Prototyping allows businesses to establish a clear objective from the start of a project. By setting a goal, such as validating a concept or assessing usability, the team can ensure that any potential problems are identified at an early stage and either fixed or avoided altogether. A well-defined prototype development process also gives stakeholders the opportunity to interact with and provide feedback on a design, ensuring that all parties are happy with its performance before investing more resources. It also encourages the use of Design for Manufacturing (DfM) principles from the outset, which ensures that the design is optimized for production and minimizes the risk of costly redesigns later on in the process.

Additive Manufacturing

Additive manufacturing aims to produce end-use parts directly from the digital design. This can significantly reduce production and supply chain costs while speeding time to market. It also allows companies to innovate with new designs and materials that may be difficult or impossible to manufacture using traditional methods.

The additive manufacturing process involves laying down layers of material, either plastic or metal, on top of each other. Each layer is melted based on the geometry suggested by the CAD model. This provides geometric freedom that opens new design paradigms, transforming the traditional ‘design for manufacturing’ approach into a’manufacture from the design’ approach.

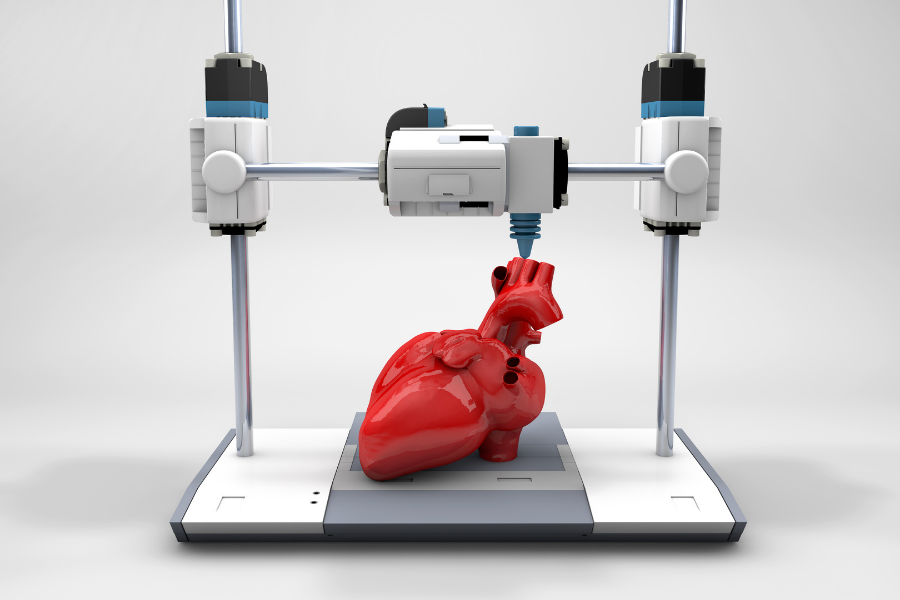

This technology can be used for a variety of industries, including aerospace, medical, automotive, and consumer products. In aerospace, 3D printing helps to streamline the supply chain by creating lightweight end-use production parts and printed tooling, reducing aircraft weight and fuel consumption. In the medical industry, additive manufacturing can be used to create surgical tools and prosthetics that are more precise, accurate and comfortable than current versions. It can also be used to print organs, which may lead to better outcomes and cost savings in many cases.

3D printing is rapidly being adopted in schools and makerspaces, as well as in engineering curricula. It is a powerful tool that helps students to gain hands-on experience and develop the skills needed for successful careers in engineering and manufacturing. This is especially important as the workforce requires more advanced and diverse technical skills.

One of the key challenges in 3D printing is ensuring that the printers are safe to use. This is because these technologies generate a lot of dust, which can contain hazardous nanomaterials. NIOSH has been conducting extensive research in the field of safe additive manufacturing. This includes laboratory-based work to address the gaps in knowledge and develop robust science, as well as field studies to assess exposures.

3D printing can also be used for distributed manufacturing and production, which helps reduce inventory costs and eliminate the need to store stock. During the pandemic, this allowed medical and healthcare companies to reduce their dependence on long supply chains and logistical costs by printing essential supplies like ventilators and masks at local locations.

Material Jetting

Material jetting is a 3D printing method that uses photopolymers to build objects. It can produce visual prototypes with high accuracy and smooth surfaces. It is also a popular choice for producing casting patterns and injection molds.

Like other 3D printing methods, a CAD model of the desired product is first created on a computer. This digital file is then cut into layers by a software program called a slicer. The individual layers are then printed with different colors and materials using a print head that incorporates multiple nozzles, allowing for full-color and multi-material printing. Objects printed with this process can be rigid or flexible, opaque or translucent, and can even have embedded electronics.

The printers used for material jetting can use a variety of photopolymer resins, with a growing number of specialized types available to meet specific requirements. These include resins optimised for optical clarity, and polymers designed to withstand high temperatures. In addition, there are currently a number of printers that can operate with water-soluble support materials, which allow for rapid clearing and washing after builds. This can lead to a significant reduction in post-processing time and costs.

This type of printer has become increasingly common in educational institutions, where it is used to teach students about the benefits and applications of additive manufacturing. Hobbyists use it to turn their CAD designs into tangible objects, and many small businesses are harnessing its power to develop prototypes and final products. By directly printing parts on demand, the technology can profoundly disrupt supply chains and introduce new efficiencies to production.

One of the biggest advantages of this process is that it eliminates the need for storage and transportation of large quantities of raw materials. It can also dramatically reduce the time to market for new products. Furthermore, it can also help to reduce the cost of manufacturing, as it is possible to print components that would not otherwise be economically viable to produce through traditional methods.

Another benefit is that it can be used to create anatomical models of the human body, allowing doctors to explain a medical procedure to their patients and surgeons to practice in advance. The ability to print parts in a range of colors allows designers to create anatomical models that are faithful to the real thing.

Material Extrusion

Material extrusion is a 3D printing technology that involves squeezing semi-liquified plastic through a nozzle (or orifice) layer by layer to build up a geometry. It is a form of additive manufacturing, and it was the second AM process to achieve commercial success, three decades after its introduction.

It is also relatively inexpensive and easy to operate. Machines require few maintenance items and are relatively safe in diverse environments from shop floors to office desks, eliminating the need for extra safety protocols. The process uses low temperatures and can print with most conventional plastics. The resulting parts typically have sufficient cosmetic and mechanical standards for many applications, including prototypes, jigs, and small pre-production batches.

This type of printer is ideal for small businesses with limited budgets and the need for high quality, accurate parts and prototypes. It is also suitable for educational institutions wishing to provide hands-on experience and experimentation with design ideas.

The process begins with the importation of a 3D model into software, which then converts it into layers that guide the operation of the machine. The software then calculates the sections and builds of the part, and the corresponding extruder paths and instructions are sent to the printing machine. The machine then deposits the raw filament or plastic in accordance with the layer information, building up the structure layer by layer until the whole geometry is printed.

When compared to traditional manufacturing methods, 3D printing produces higher-quality products because the steps are done precisely. This ensures that the end result is exactly as planned, and it eliminates potential defects like air bubbles or uneven surfaces.

Another advantage of the technology is that it can produce complex geometries that are impossible to make using traditional machining techniques. For example, it can create internal voids to lighten the product, a feature that is especially useful in aerospace and defense industries. It can also enable designers to add details that would be impossible or cost-prohibitive in traditional machining, such as threading.

For example, in aerospace applications, it is possible to create intricate, lightweight structures that reduce the weight of aircraft and increase their fuel efficiency. The process also allows for a more compact assembly, saving space on the plane or vehicle.